They say that every cloud has a silver lining..

It is going to be a big opportunity for India.. we should strive to bring major Brands to India.

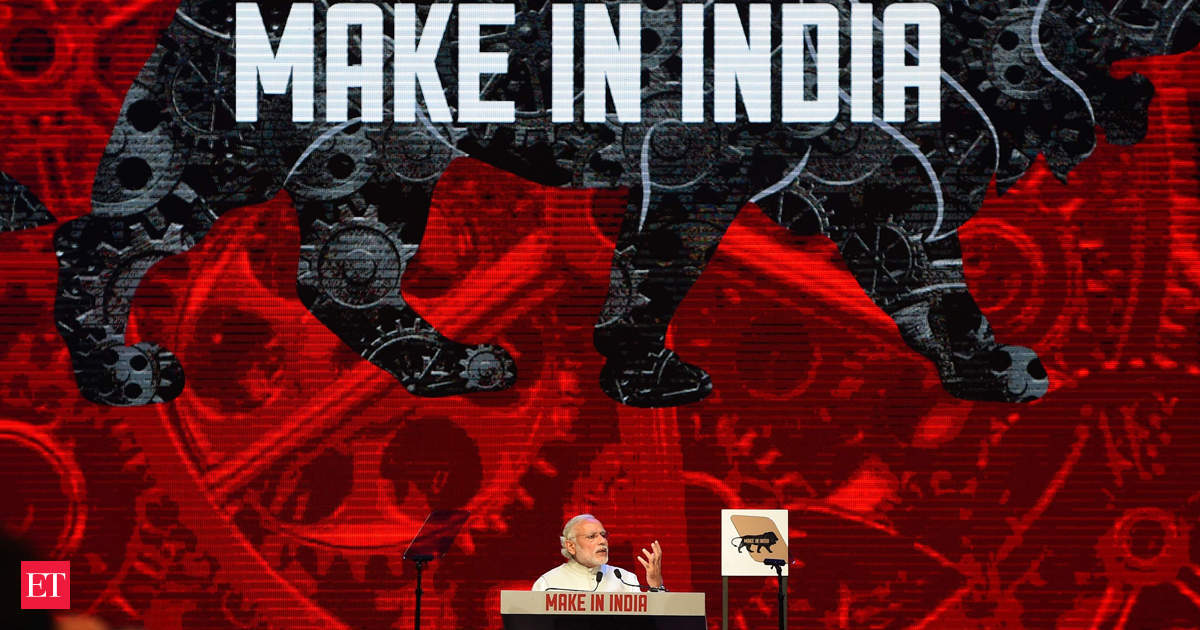

It may prove a major boost for the 'MAKE IN INDIA' project.

About 200 US companies seeking to move manufacturing base from China to India: USISPF

About 200 American companies are seeking to move their manufacturing base from China to India post the general elections, a top US-based advocacy group has said, observing that there is a fantastic opportunity with firms looking at alternatives to the Communist giant.

The US-India Strategic and Partnership Forum's (USISPF) President Mukesh Aghi said that the companies are talking to them about how to set up an alternative to China by investing in India.

Aghi said that USISPF's recommendation to the new government would be to accelerate the reforms and bring transparency in the decision-making process.

“I think that's critical. We would advise to bring more transparency in the process and to make it more consultative because in the last 12 to ..

Read more at:

economictimes.indiatimes.com

economictimes.indiatimes.com

It is going to be a big opportunity for India.. we should strive to bring major Brands to India.

It may prove a major boost for the 'MAKE IN INDIA' project.

About 200 US companies seeking to move manufacturing base from China to India: USISPF

About 200 American companies are seeking to move their manufacturing base from China to India post the general elections, a top US-based advocacy group has said, observing that there is a fantastic opportunity with firms looking at alternatives to the Communist giant.

The US-India Strategic and Partnership Forum's (USISPF) President Mukesh Aghi said that the companies are talking to them about how to set up an alternative to China by investing in India.

Aghi said that USISPF's recommendation to the new government would be to accelerate the reforms and bring transparency in the decision-making process.

“I think that's critical. We would advise to bring more transparency in the process and to make it more consultative because in the last 12 to ..

Read more at:

About 200 US companies seeking to move manufacturing base from China to India: USISPF

The firms have been making queries on how to set up an alternative to China by investing in India.

Last edited: